Dura-Bar 60-40-18 is a nodular iron with a fully ferritic matrix. This iron grade’s microstructure is achieved through annealing and offers excellent ductility and impact strength. Dura-Bar 60-40-18 has the most ductility out of the ductile iron family of Dura-Bar. Annealed Dura-Bar is NACE compliant, ASTM A395, and ASTM A536. To learn more, download the 60-40-18 Ductile Iron Product Brief.

Gears

Cylinder Blocks, End Caps, Gear Rack Housings, Gerotors, Glands, Manifolds, Pistons, Rotors, Valves

Bank Molds, Plungers

Barrell Rollers, Bushings, Chain Sheave Rollers, Chuck Bodies, Die Blocks, Flywheels, Gear Racks, Gears, Housings, Pile Drivers, Press Rams, Pulleys, Rams, Rotary Tables

Port Plate

Gears, Pulleys

Gears, Housings, Pistons, Rotors

Guide Rolls, Pinch Rolls, Runout Table Rolls

Camshafts, Carriers, Gears, Pulleys, Rail Spacers

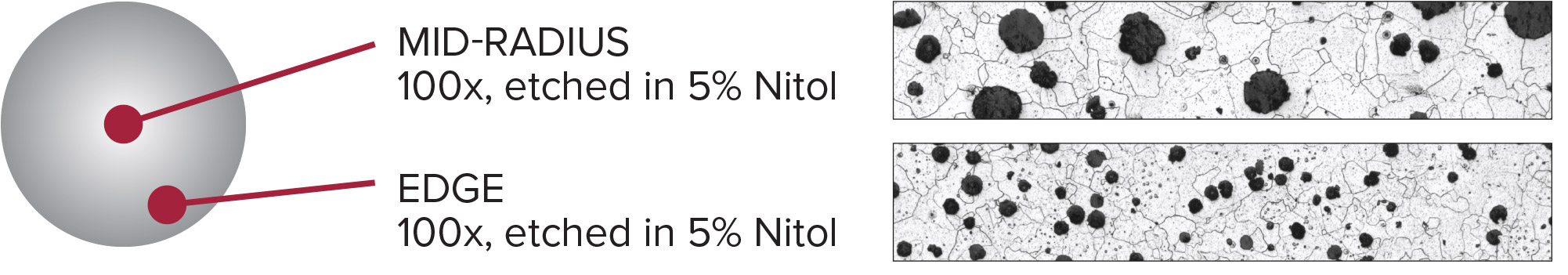

The microstructure consists of Types I & II nodular graphite as defined in ASTM A247. The matrix is 100% ferrite. The edge or rim will have a higher nodular count. Chill carbides will be less than 5% in any field at 100x and will be well dispersed.

Dura-Bar Ductile 60-40-18 is a non-stock grade, which can be ordered in volume quantities from our distributors.

*Carbon and silicon targets are specified for each bar size in order to maintain mechanical properties. Magnesium is added as an inoculant to produce nodular graphite.

| Element | Percentage |

|---|---|

| Carbon | 3.50–3.90% |

| Silicon | 2.25–3.00% |

| Manganese | 0.15–0.35% |

| Sulfur | 0.025% Max |

| Phosphorus | 0.05% Max |

Hardness properties for various diameters are shown in the table. Hardness properties listed are minimum and maximum across the bar. For rectangles, squares and shapes, the hardness properties will depend on minimum and maximum section thickness and will be supplied on request.

| Size Range | BHN | ||

|---|---|---|---|

| Inches | mm | Min | Max |

| 2.500–3.500 | 64–89 | 148 | 165 |

| 3.501–4.500 | 89–114 | 151 | 161 |

| 4.501–5.500 | 76–140 | 152 | 162 |

Tensile strength is determined from a longitudinal test specimen taken from the mid-radius of the as-cast bar.

| Mechanical Properties | |

|---|---|

| Tensile strength psi (min) | 60,000 |

| Yield strength psi (min) | 40,000 |

| Elongation (min) | 18% |