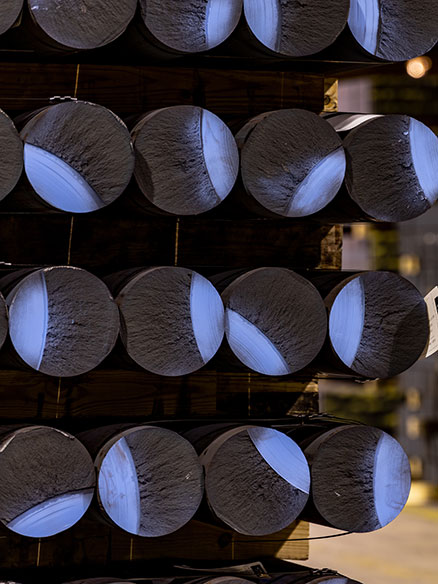

80-55-06X is a grade of ductile iron available in larger rounds and rectangles. This grade tends to contain more pearlite making the material a good fit in applications where considerations to wear resistance and surface finish are required. The additional pearlite also makes this material responsive to heat treating, like through-hardening and surface hardening. Download the 80-55-06X Product Brief, or X Products for all X grades.

Gears

Cylinder blocks, Gerotors, Glands, Manifolds, Pistons, Rotors, Valves

Barrell Rollers, Bushings, Chain Sheave Rollers, Chuck Bodies, Die Blocks, Flywheels, Gear Racks, Gears, Housings, Pile Drivers, Press Rams, Pulleys, Rams, Rotary Tables, Tie Rod Nuts

Core Boxes, Dies, Disamatic Pouring Rails, Grinding Rolls, Mill Liners , Pattern Plates, Plunger Pin

Gears, Pulleys

Gears, Housings, Liners, Pistons, Rotary Screws, Rotors

Guide Rolls, Pinch Rolls, Runout Table Rolls

Gears, Motorcycle Disk Brake, Pulleys, Rail Spacers

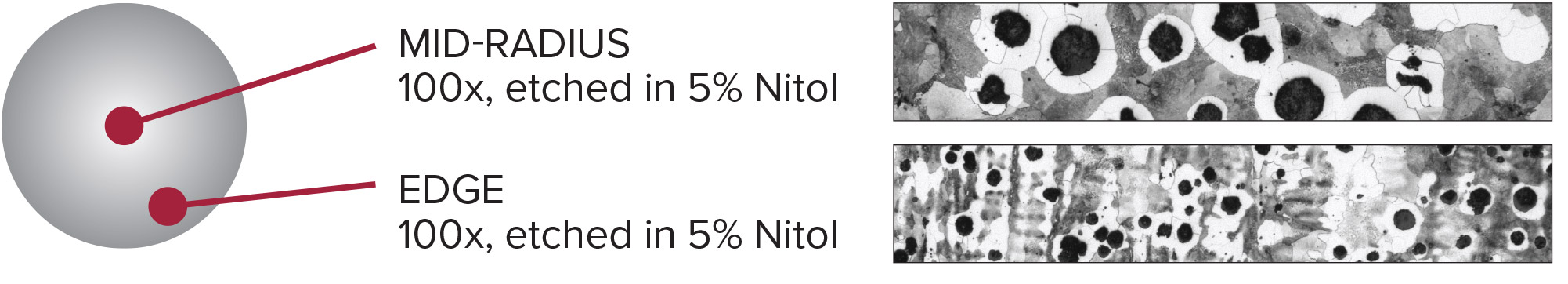

The microstructure consists of Type I & Type II nodular graphite as defined in ASTM A247. The matrix is pearlite and ferrite. The edge or rim has a higher nodule count and a mixture of ferrite and pearlite. Chill carbides will be less than 5% in any field at 100x and will be well dispersed.

Magnesium is added as an inoculant to produce nodular graphite. Small amounts of alloying elements are used to stabilize the pearlitic structure.

| Element | Percentage |

|---|---|

| Carbon | 3.20 – 3.85% |

| Silicon | 2.20 – 3.10% |

| Manganese | 0.10 – 0.55% |

| Sulfur | 0.02% Max |

| Phosphorus | 0.08% Max |

Hardness properties listed are minimum and maximum across the bar. For rectangles and squares the hardness properties will depend on minimum and maximum section thickness and will be supplied on request.

Size Ranges

| Inches | Millimeter |

|---|---|

| 1.000 - 28.000 | 25 - 711 |

BHN

| Inches | Millimeter |

|---|---|

| 187 | 255 |

Tensile strength is determined from a longitudinal test specimen taken from mid-radius of the as-cast bar.

| Mechanical Properties | |

|---|---|

| Tensile strength psi (min) | 80,000 |

| Yield strength psi (min) | 55,000 |

| Elongation (min) | 6% |