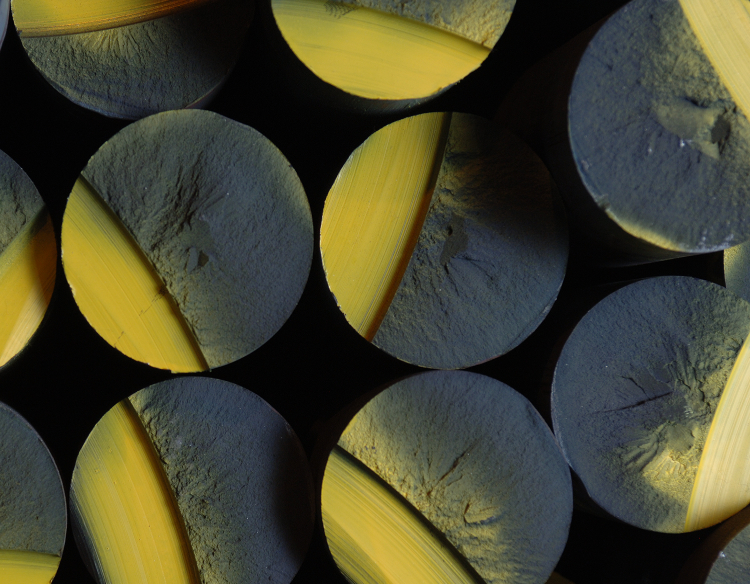

GX is a pearlitic gray iron offered in a variety of small and large rounds and rectangles for non-typical size applications. GX benefits include wear resistance, noise and vibration damping, and can be heat treated using conventional methods. Download the GX Gray Iron Product Brief, or X Products for all X grades.

Gears

Cylinder blocks, Glands, Manifolds, Pistons, Rotors, Spools, Valves

Bushings, Gears, Gibs, Housings, Pulleys, Rams, Sheaves, Side Frames, Slides, Spindles, Ways

Aluminum Molds Plates, Cams, Chain Sheaves, Core Boxes, Dies, Pattern Plates, Wheels

Bridge Plugs, Cement Plugs, Cones, Mandrels, Retainers, Slips

Gears, Pulleys

Gears, Housings, Liners, Pistons, Rollers, Rotors, Seals

Continuous Caster Rolls, Pattern Plates, Core Box Patterns, Foot Rolls, Table Rolls, Torch Rolls

Brake Rotors, Cylinder Liners, Gears, Lash Adjusters, Pulleys, Shock Absorber Pistons, Valve Guides, Valve Seat Inserts

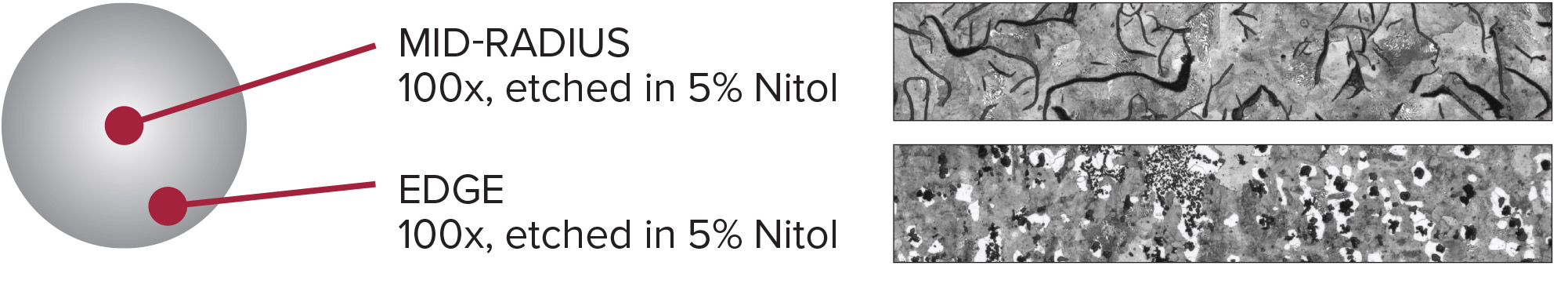

The core microstructure will consist of Type A graphite flake, per ASTM A247, with a matrix containing a minimum of 90% pearlite. The edge or rim will have a combination of Type D and Type E graphite flake and a matrix with a mixture of ferrite and pearlite. The rim will contain as much as 5% carbides.

| Element | Percentage |

|---|---|

| Carbon | 2.70 - 3.45% |

| Silicon | 2.10 - 2.90% |

| Manganese | 0.50 - 0.90% |

| Sulfur | 0.04 - 0.1% |

| Phosphorus | 0.15% Max |

Hardness values listed are minimum and maximum across the bar. Hardness values for rectangles and squares are a function of the height and width ratios and will be supplied on request.

Size Range

| Inches | Millimeters |

|---|---|

| 1.000 - 28.000 | 25 - 711 |

BHN

| Min | Max |

|---|---|

| 183 | 285 |

Tensile Strength

GX conforms to ASTM A48 Class 40 - download the GX Class 40 Tensile Table. Tensile data from the as-cast bar in conjunction with separately cast tensile data, correlates to a Class 40 Gray Iron.