Dura-Bar SSDI is a grade of ductile iron that combines the elevated mechanical strengths of a pearlitic ductile iron with the machinability advantages of a ferritic ductile iron. By combining the best of both desired properties, Dura-Bar SSDI is an attractive grade of ductile iron that provides several benefits towards designing and manufacturing of metal components. Download the SSDI Product Brief or the SSDI Sales Flyer to learn more.

Compressors Rotors, Hydraulic Manifolds & Cylinders.

Plug Value Inserts and Crossheads

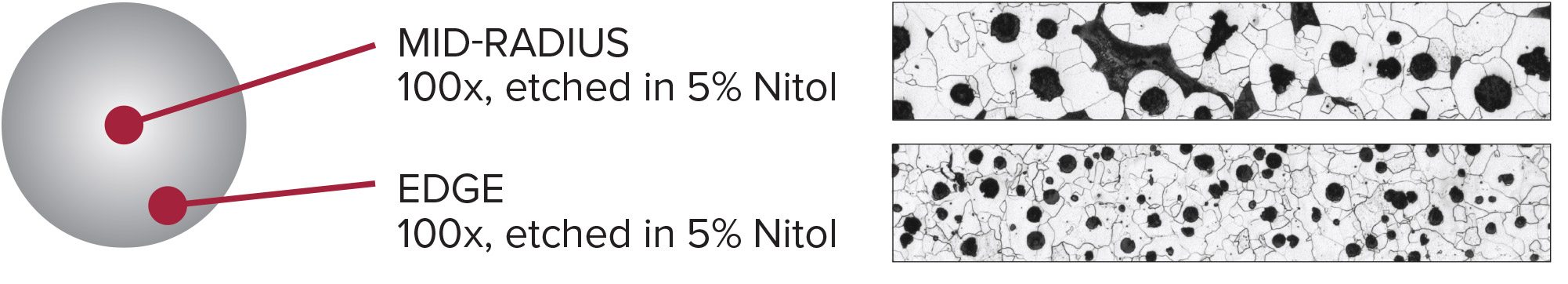

The microstructure consists of Types I & II nodular graphite. Microstructure attributes can be summarized as 85% nodularity. Pearlite percentage for the center and edge of the bar is 5–30% and 0–15%, respectively.

*Carbon and silicon targets are specified for each bar size in order to maintain mechanical properties. Magnesium is added as an inoculant to produce nodular graphite.

| Element | Percentage |

|---|---|

| Carbon* | 3.20–3.75% |

| Silicon* | 3.25–4.00% |

| Manganese | 0.15–0.35% |

| Sulfur | 0.025% Max |

| Phosphorus | 0.05% Max |

Hardness properties for various diameters are shown in the table. Hardness properties listed are minimum and maximum across the bar. For rectangles, squares and shapes, the hardness properties will depend on minimum and maximum section thickness and will be supplied on request.

Size Ranges

| Inches | Millimeters |

|---|---|

| 1.000–20.000 | 25–508 |

BHN

| Min | Max |

|---|---|

| 167 | 229 |

Tensile strength is determined from a longitudinal test specimen take from mid-radius of the as-cast bar.

| Mechanical Properties | |

|---|---|

| Tensile strength psi (min) | 75,000 |

| Yield strength psi (min) | 55,000 |

| Elongation (min) | 15% |