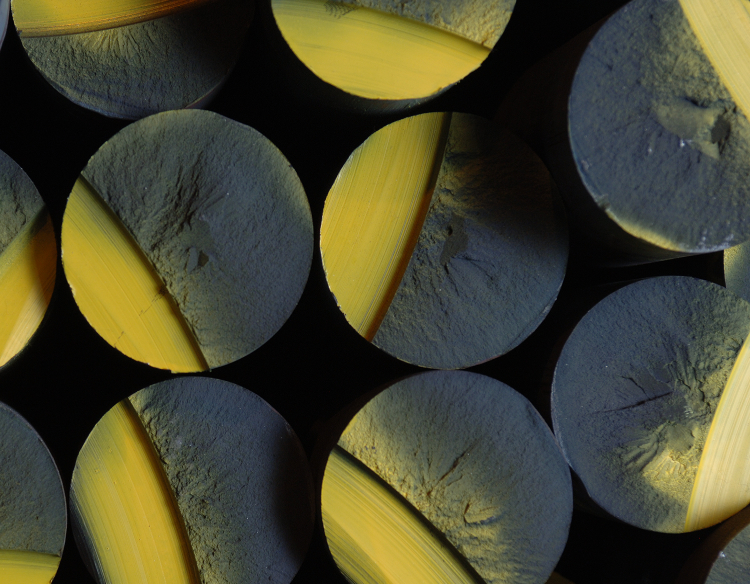

Dura-Bar G2P is a highly pearlitic gray iron containing Type A graphite. It was developed to best suit surface-hardenability applications. G2P is made with a substantial amount of pearlite in the rim. This requires the least amount of stock removal necessary, in order to achieve a heat-treatable surface. Carbon-rich material is forced to the outer edges of the bars. This allows the surface hardening via heat treatment (induction and flame hardening) to be accomplished quickly, consistently, and effectively. To learn more, download the G2P Gray Iron Product Brief.

Gears

Cylinder blocks, Glands, Manifolds, Pistons, Rotors, Spools, Valves

Bushings, Gears, Gibs, Housings, Pulleys, Rams, Sheaves, Side Frames, Slides, Spindles, Ways

Aluminum Molds Plates, Cams, Chain Sheaves, Core Boxes, Dies, Pattern Plates, Wheels

Bridge Plugs, Cement Plugs, Cones, Mandrels, Retainers, Slips

Gears, Pulleys

Gears, Housings, Liners, Pistons, Rollers, Rotors, Seals

Continuous Caster Rolls, Foot Rolls, Table Rolls, Torch Rolls

Brake Rotors, Cylinder Liners, Gears, Lash Adjusters, Pulleys, Shock Absorber Pistons, Valve Guides, Valve Seat Inserts

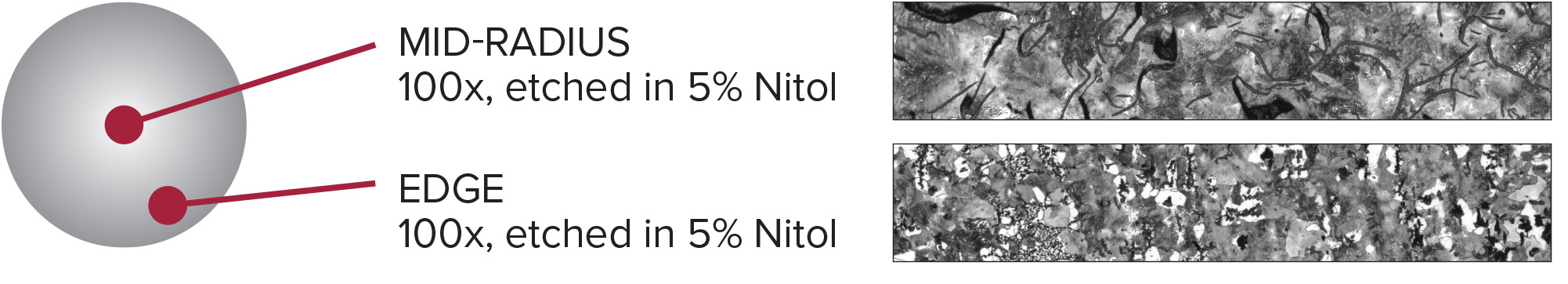

The microstructure will contain Type VII, A, size 4-6 graphite as defined in ASTM A247. The matrix is fully pearlitic. The edge or rim will consist of Type D, size 6-8 graphite in a matrix that is 80% pearlite. Chill carbides will be less than 5% in any field at 100x and are well dispersed.

Carbon and silicon targets are specified for each bar size in order to control the size and shape of the graphite flake. Alloying elements are used to stabilize the pearlitic structure.

| Element | Percentage |

|---|---|

| Carbon | 2.60 - 3.75% |

| Silicon | 1.80 - 3.00% |

| Manganese | 0.60 - 0.95% |

| Sulfur | 0.07% Max |

| Phosphorus | 0.12% Max |

Brinell hardness values for nominal as-cast diameters are shown in the table. Hardness properties listed are minimum and maximum across the bar. Hardness values for rectangles and squares are a function of the height and width ratios and will be supplied on request.

Size Range

| Inches | Millimeters |

|---|---|

| 0.625 - 0.750 | 16 - 19 |

| 0.751 - 3.000 | 19 - 75 |

| 3.001 - 6.000 | 76 - 152 |

| 6.001 - 22.000 | 152 - 559 |

BHN

| Min | Max |

|---|---|

| 229 | 302 |

| 207 | 302 |

| 197 | 302 |

| 183 | 302 |

Tensile strength is determined from a separately cast, ASTM "B" test bar. Separately cast test bars will meet the minimum strength in pounds per square inch in the table. Additionally, a test bar is removed from the continuous cast bar for reference, since tensile strength varies with section thickness and bar diameter.

| Mechanical Properties | |

|---|---|

| Tensile strength psi (min) | 40,000 |

| Yield strength psi (min) | n/a* |

| Elongation (min) | n/a* |

*Gray iron will not yield/elongate before fracture. The behavior of gray iron is non-ductile.